Tools to help prevent production loss and unplanned downtime

THE CUSTOMER’S CHALLENGE

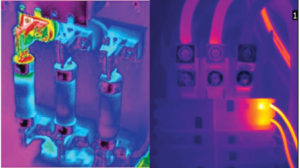

When electrical connections and components break down unexpectedly, a lot can go wrong. Production loss, unplanned downtime, and electrical fires are all possible outcomes-and they can be costly. Electrical connections and components tend to overheat before they fail, but this can be difficult to detect with the naked eye. Maintenance professionals need a fast, easy, and reliable way to catch temperature problems early in order to organize planned repairs and preventive maintenance before it’s too late.

A SOLUTION

Thermal imaging technology can provide maintenance professionals with key temperature information that the eyes alone cannot detect. Conducting electrical panel inspections using a thermal camera like the FLIR T540 can reveal stressed elements of the electrical installation before a failure occurs. This provides the opportunity to plan maintenance and solve electrical issues before they create a serious and costly problem. FLIR also produces handheld portable cameras, fixed-mount cabinet cameras, digital multimeters, and clamp meter solutions that can detect and confirm issues. For high-voltage cabinets or inaccessible components, FLIR IR windows can be easily mounted on the front panel, so maintenance professionals can perform visual and thermal inspections without opening the panel door or powering down the circuits.

temperature issues that point to problems with electrical components and equipment.

THE RESULTS

Through regular thermal inspections, maintenance professionals can reduce the risk of electrical fire, reduce the risk of unplanned electrical outages, and reduce the number of unexpected breakdowns by 90 percent. Using a thermal imager, they can rapidly detect and locate temperature issues of electrical components and equipment. Problems including loose connections, bad contacts, fuse issues, unbalanced loads, and stressed earth leakage result in high temperatures that can be clearly detected using a thermal imager. After each inspection, visual and thermal images of the defective component may be stored and reported with a diagnostic failure and corrective action request, set per level of priority.

For more information about FLIR in manufacturing or to schedule a

product demonstration visit: www.flir.in/manufacturing/electrical-systems

FLIR Systems India Pvt. Ltd.

1111, D Mall, Netaji Subhash Place, Pitampura, New Delhi – 110034

Tel: +91-11-4560 3555 Fax: +91-11-4721 2006

E mail: [email protected]